Why Ransomware is a Growing Threat in Manufacturing Plants

October 12, 2025

Introduction

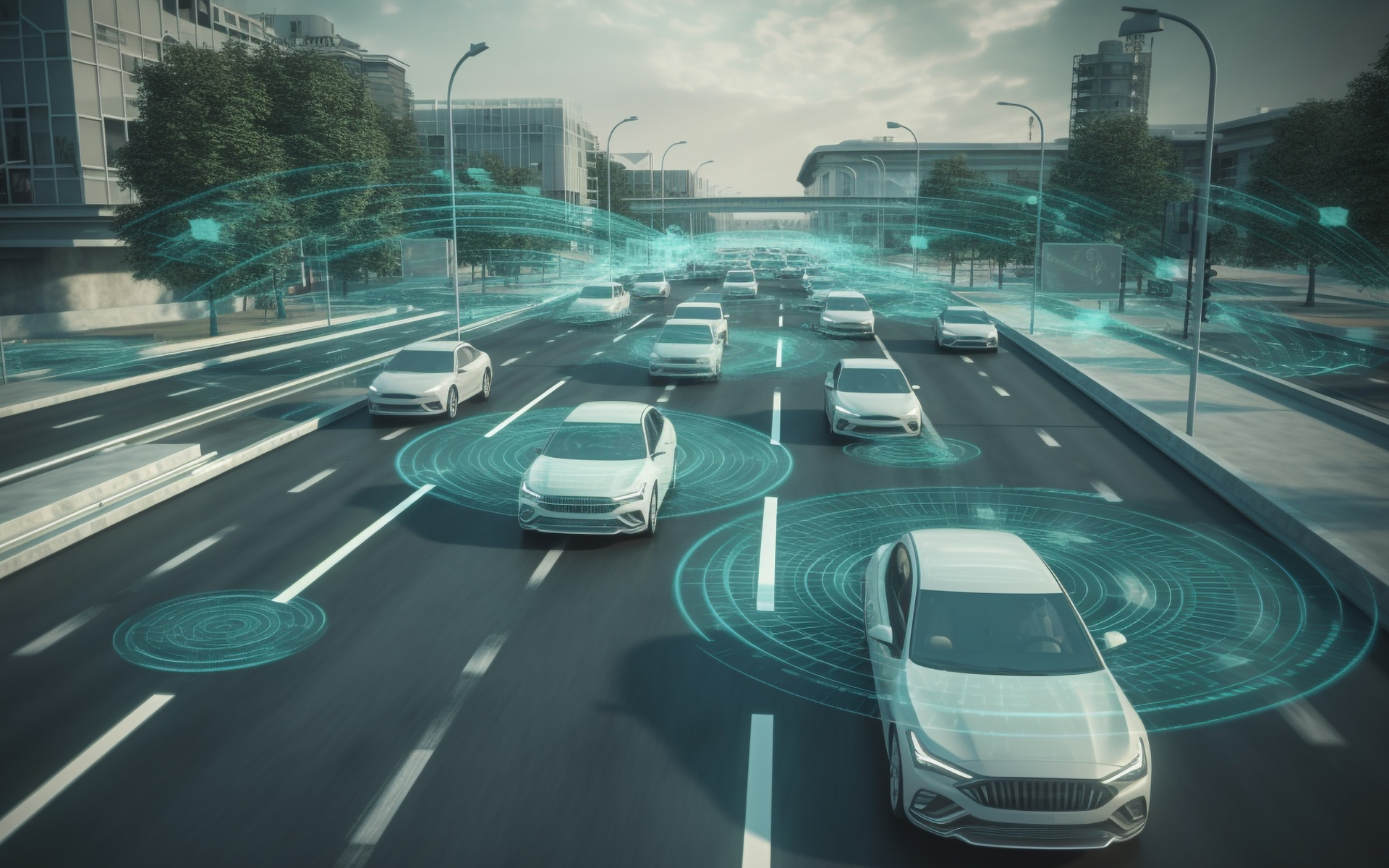

Ransomware has become one of the most damaging cyber threats facing global industry. Over the past few years, manufacturing plants have become a preferred target for criminal groups. Attackers exploit weaknesses in industrial networks, operational technology, and human behaviour to lock down production systems and demand payment. This problem has escalated as manufacturing moves toward digital automation, connected supply chains, and remote monitoring.

This blog is for business leaders, operations managers, and cybersecurity professionals who manage or support manufacturing facilities. The aim is to explain why ransomware is increasing in this sector, what weaknesses attackers exploit, and how you can protect your organisation.

Ransomware refers to malicious software that encrypts files or systems and prevents access until a ransom is paid. The attackers usually request payment in cryptocurrency to remain anonymous. For manufacturing, this means production can stop instantly. Machines become inoperable, logistics halt, and safety systems can fail. Unlike other sectors, downtime in manufacturing translates into immediate financial and reputational loss.

The manufacturing industry is now the most targeted sector for ransomware according to the IBM X-Force Threat Intelligence Index 2024, which reported that 25 percent of all ransomware attacks in 2023 hit manufacturers (IBM, 2024). The reason is simple. Manufacturers depend on continuous production. Any downtime costs millions. Attackers know this and use it to pressure companies into paying quickly.

The Rise of Ransomware in Manufacturing

Ransomware has evolved from simple file-locking malware into complex operations run by organised groups. These groups operate like businesses. They use affiliate programs, offer customer support for ransom payments, and deploy advanced techniques to evade detection. The growth of “ransomware-as-a-service” means even low-skill criminals can launch attacks by renting tools from more experienced operators.

Between 2020 and 2024, the average global cost of a ransomware incident rose from £600,000 to over £1.6 million, according to Sophos (Sophos, 2024). In the manufacturing sector, the average downtime per incident increased to 21 days, showing how devastating these attacks have become.

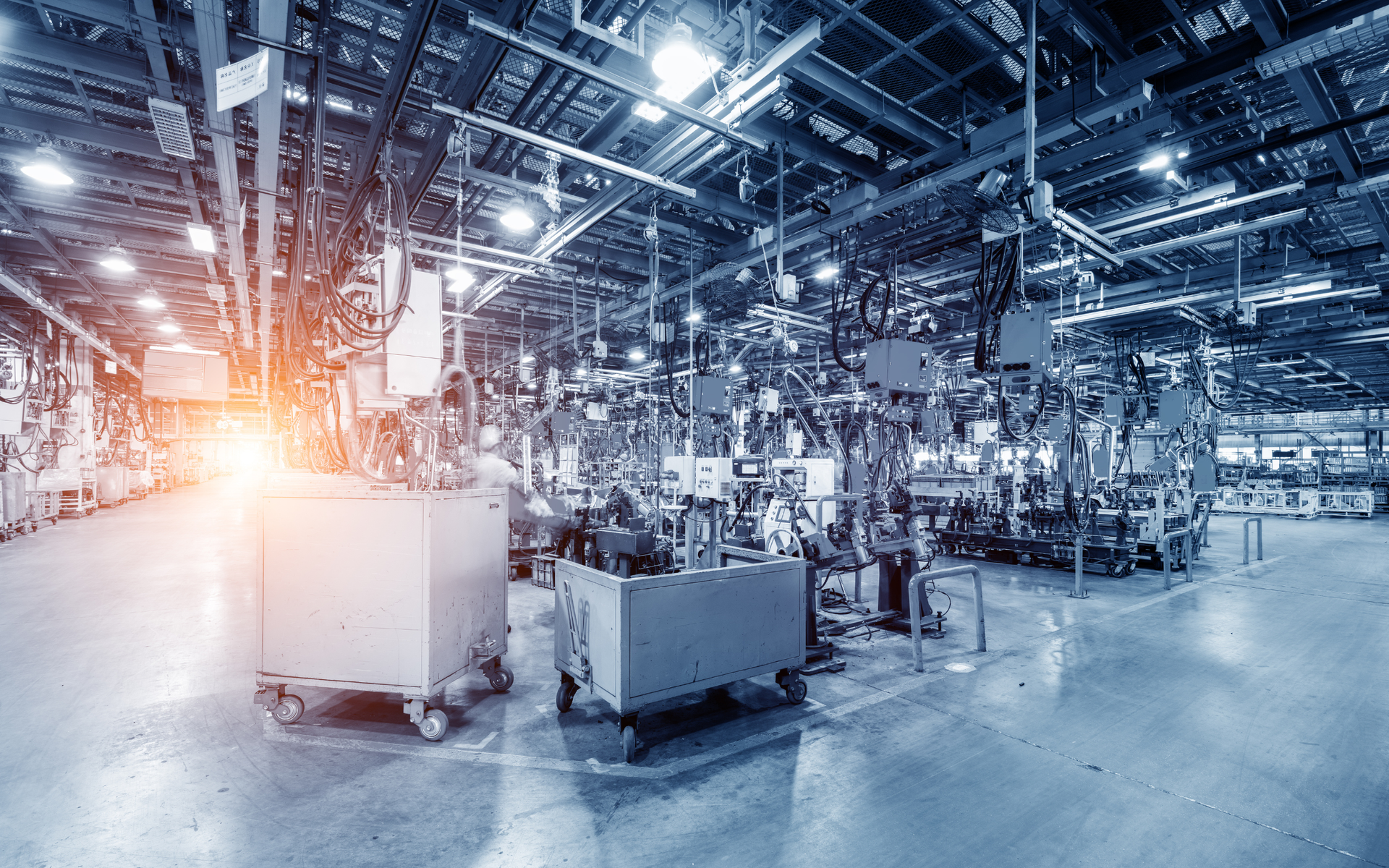

Manufacturing plants face unique challenges. Many rely on legacy industrial control systems that were never designed for internet connectivity. As more facilities adopt digital transformation projects and connect machines to corporate networks, they expose themselves to cyber risks.

Attackers often gain access through poorly secured remote desktop services, phishing emails, or vulnerabilities in software. Once inside, they move laterally to control critical systems.

A well-known example is the 2022 attack on a global automotive manufacturer. Operations in several European plants were suspended for days after ransomware spread through the company’s network. Production delays affected supply chains and cost millions in lost output. In another case, a food packaging company in the UK suffered a ransomware attack in 2023 that disrupted orders for weeks. The attackers demanded £5 million for decryption keys and threatened to leak confidential design data online.

The increase in attacks reflects a broader trend. Manufacturing is attractive to criminals because it combines valuable intellectual property, strict deadlines, and operational urgency. Attackers know that production loss is intolerable, which makes companies more likely to pay.

The Importance of Protecting Airport Data Systems

Airports process vast amounts of data every minute. Passenger details, payment information, flight schedules, and biometric records all move through interconnected systems. Protecting this information is vital to prevent identity theft, fraud, and reputational loss.

Passenger data is one of the most valuable targets for cybercriminals. In 2018, British Airways suffered a major data breach affecting over 400,000 customers, leading to a £20 million fine under the UK General Data Protection Regulation (Information Commissioner’s Office, 2020). The incident highlighted the financial and operational consequences of weak cybersecurity controls.

Effective cybersecurity in airports must therefore protect both operational technology (OT) and information technology (IT). OT includes systems that manage physical processes, such as airfield lighting, HVAC systems, and access control. IT systems manage digital processes, including passenger databases, ticketing platforms, and airline communication networks. A failure in either category can disrupt airport operations.

As airports introduce more Internet of Things (IoT) devices, the attack surface expands. Sensors monitoring air quality, baggage location, or temperature are often connected to central control systems. If not properly secured, these endpoints become potential entry points for attackers.

To reduce this risk, airports should adopt a zero-trust architecture. This approach assumes that no device or user is trusted by default. Every request must be verified before access is granted. It is a proactive strategy that limits the spread of threats across systems.

Strong data protection also builds trust with passengers. Travellers expect airports to safeguard their information with the same diligence applied to physical security. By implementing comprehensive cybersecurity measures, airports strengthen both compliance and reputation.

Why Manufacturing Plants Are Prime Targets

Manufacturing plants operate complex environments that combine information technology and operational technology. This convergence creates more attack points. Industrial control systems often run on outdated software or are difficult to patch because shutting them down disrupts production. Many organisations lack visibility across both networks.

Cybersecurity teams in manufacturing often focus on safety and reliability. Security comes later. This creates weak spots that attackers exploit. A single unpatched system, outdated firewall, or misconfigured remote access gateway can provide entry.

Phishing remains one of the most effective methods for initial compromise. Attackers send employees emails disguised as purchase orders or supplier communications. When opened, these messages deploy malware that spreads across the network. Once inside, attackers use tools such as Cobalt Strike or Mimikatz to escalate privileges and encrypt systems.

The supply chain adds another layer of risk. Manufacturing plants depend on suppliers for parts, maintenance, and logistics. If a supplier is compromised, attackers can move into your network. This happened in the 2021 attack on a large global meat processor. The attackers entered through a trusted vendor connection and encrypted the production systems across multiple countries.

Many factories also rely on outdated versions of Windows or legacy SCADA systems. Some machines run continuously for decades without software updates. Attackers exploit these old systems because they often lack basic protections like multi-factor authentication or network segmentation.

The Cost of Ignoring the Threat

When ransomware strikes a manufacturing plant, the financial and operational consequences are severe. Production stops, deliveries fail, and revenue disappears. Recovery costs include data restoration, system rebuilding, forensic investigation, and lost business. The reputational damage is long-term. Clients lose confidence, insurance costs rise, and regulatory scrutiny increases.

In 2023, the UK’s National Cyber Security Centre (NCSC) reported a 40 percent increase in ransomware incidents affecting manufacturing. Losses ranged from tens of thousands to millions of pounds per event (NCSC, 2023). Many organisations that paid the ransom never recovered all their data. Others faced data leaks despite paying.

Beyond financial losses, safety risks are significant. If a production line stops mid-cycle, equipment can be damaged or cause injury. Some ransomware variants target safety controllers and programmable logic devices. The LockerGoga and Snake ransomware families were designed to disrupt industrial processes directly.

Ignoring this threat also breaches compliance obligations. Regulations such as the UK’s Network and Information Systems Regulations 2018 require operators of essential services to manage cybersecurity risks. Failure to do so can result in penalties and legal action.

Understanding the Ransomware Lifecycle

Ransomware attacks follow a structured process. Understanding this helps defenders detect and stop attacks earlier.

Attackers begin by scanning the internet for exposed systems. They then gain entry through weak passwords, phishing emails, or compromised suppliers. Once inside the network, they spend days or weeks exploring. Their goal is to find valuable systems, disable backups, and identify data to encrypt.

Next comes privilege escalation. Attackers gain administrator access and spread across the network. They disable antivirus tools and security logs to avoid detection. When ready, they launch encryption simultaneously across systems to cause maximum disruption.

After encryption, a ransom note appears demanding payment. Attackers often use double or triple extortion. They threaten to publish stolen data or contact customers directly. Some groups also use distributed denial of service attacks to pressure victims further.

Understanding this sequence allows defenders to deploy layered protection. The earlier an attack is detected, the less damage it causes.

How to Reduce Ransomware Risk

Strong cybersecurity requires both technical and procedural defences. Start by assessing your exposure. Identify which systems are critical for operations and where vulnerabilities exist. Segment operational technology from corporate networks. This limits the spread of malware if one area is compromised.

Apply security patches promptly. Many ransomware attacks exploit known vulnerabilities that remain unpatched for months. Implement strict access control and remove unused remote connections. Use multi-factor authentication for all administrative accounts.

Regular backups are essential. Store backups offline or in immutable storage that cannot be altered by ransomware. Test restoration procedures regularly. An untested backup is unreliable.

Employee awareness is equally important. Most successful attacks begin with phishing. Conduct regular training sessions so staff can identify suspicious emails. Use simulated phishing exercises to test readiness.

Adopt established cybersecurity frameworks. The UK’s Cyber Essentials scheme provides a practical baseline. It helps organisations prevent 80 percent of common cyber attacks. For larger facilities, follow the NIST Cybersecurity Framework or ISO/IEC 27001 standards to structure your controls.

Monitor your network continuously. Deploy intrusion detection systems and endpoint protection tools that identify abnormal behaviour. Many organisations now use Managed Detection and Response services to gain 24/7 monitoring.

Prepare an incident response plan. When ransomware hits, rapid action reduces impact. Your plan should define who to contact, how to isolate affected systems, and how to restore operations safely. Conduct regular simulations to ensure your team is ready.

Real-World Case Studies

Colonial Pipeline (2021)

Although not a manufacturing plant, the Colonial Pipeline attack demonstrates the scale of disruption ransomware can cause to operational technology. A single compromised password led to a shutdown of fuel supply across the eastern United States. The company paid approximately £3.5 million in ransom (BBC, 2021). The case shows how interconnected systems can magnify impact.

Norsk Hydro (2019)

Norwegian aluminium producer Norsk Hydro was hit by the LockerGoga ransomware. The attack stopped production in several plants. The company refused to pay and restored operations using backups. Recovery costs exceeded £50 million (Reuters, 2019). Norsk Hydro’s transparency in reporting the incident became a model for responsible response.

UK Manufacturing Firm (2023)

In 2023, a medium-sized UK plastics manufacturer faced a ransomware attack that encrypted its production servers. The company lost three weeks of output and paid £1.2 million in recovery costs. Investigation found that the attackers entered through an unpatched VPN appliance. This case highlights how common misconfigurations open doors for criminals.

Each of these incidents demonstrates that ransomware does not only target large corporations. Small and medium enterprises face equal risk because attackers automate scanning for vulnerable systems across all sectors.

The Role of Leadership in Cyber Resilience

Cybersecurity is not only a technical issue. It is a leadership responsibility. Senior managers must treat ransomware as a business risk. Investment in cybersecurity should be proportionate to operational value. Leaders should integrate cyber resilience into corporate governance and risk management frameworks.

Encourage a culture of security awareness. Staff at all levels should feel responsible for protecting systems. Security should be part of performance metrics. Communication between IT, OT, and executive teams is essential. Decisions about new technologies or suppliers must consider cybersecurity implications from the start.

Board members should receive regular reports on cyber readiness and test the organisation’s response to simulated attacks. This ensures decision-makers understand both technical and financial exposure.

Building a Resilient Future

Ransomware will continue to evolve. Attackers are adopting artificial intelligence to automate intrusion and encryption. They use data analysis to identify the most profitable targets. As manufacturing becomes more connected through Industry 4.0 technologies, exposure grows.

Resilience requires continuous improvement. Organisations must move from reactive defence to proactive risk management. This means continuous monitoring, regular assessments, and partnership with cybersecurity experts.

Investing in secure design at the planning stage of production systems prevents future vulnerability. Isolating legacy equipment and upgrading obsolete software are key steps. Collaboration within the manufacturing community also helps. Sharing threat intelligence between industry peers, government agencies, and security vendors strengthens collective defence.

Training and awareness will always be central. Human error remains the most exploited weakness. Regular exercises help maintain readiness and build confidence.

Manufacturing is the foundation of the economy. Protecting it from ransomware protects supply chains, jobs, and national infrastructure.

Summary

Ransomware is now the most serious cyber threat facing manufacturing plants. Attackers target this sector because disruption is costly and urgent. Every plant must assume it will be targeted and prepare accordingly.

Implementing strong security controls, training staff, maintaining backups, and developing an incident response plan are critical steps. Adopting recognised frameworks such as Cyber Essentials or ISO/IEC 27001 strengthens resilience. Leadership commitment ensures long-term protection.

Ransomware attacks are not unstoppable. With preparation, awareness, and investment in cyber defence, manufacturers can protect their operations and maintain trust with customers and partners.

References

BBC. (2021) Colonial Pipeline: Ransomware Attack Causes Fuel Shortages in the US. BBC News.

IBM. (2024) X-Force Threat Intelligence Index 2024. IBM Security.

National Cyber Security Centre. (2023) Annual Review 2023. NCSC, UK.

Reuters. (2019) Norsk Hydro Cyber Attack Costs Up to £50 Million. Reuters News.

Sophos. (2024) State of Ransomware Report 2024. Sophos Ltd.

Ready to strengthen your security posture? Contact us today for more information on protecting your business.

Let's get protecting your business

Thank you for contacting us.

We will get back to you as soon as possible.

By submitting this form, you acknowledge that the information you provide will be processed in accordance with our Privacy Policy.

Please try again later.

Cybergen News

Sign up to get industry insights, trends, and more in your inbox.

Contact Us

Thank you for subscribing. It's great to have you in our community.

Please try again later.

SHARE THIS

Latest Posts